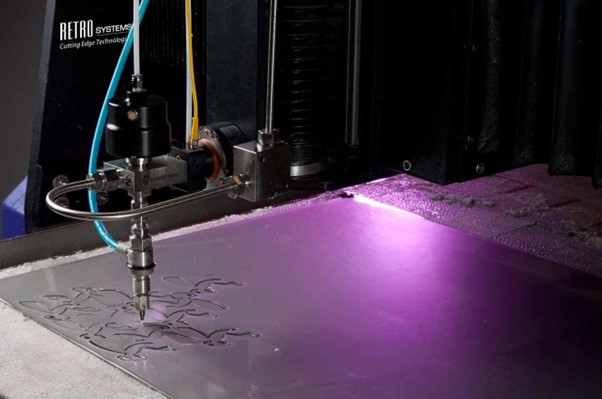

If your manufacturing business has a need to cut through metal and other materials with precision and accuracy, waterjet cutting might be the right option for you. This process uses high-pressure jets of water to create clean, accurate cuts. It is a popular choice for businesses that need to cut through a variety of materials quickly and efficiently.

Waterjet cutting is a versatile technology that can be used to cut through a variety of materials, including metal, stone, glass, and plastic. The process is extremely accurate and can produce clean cuts with little or no burrs. Waterjet cutting is also faster than traditional methods such as sawing or grinding, which means that you can complete projects in a shorter amount of time.

Waterjet cutters are made to handle large projects and can cut through materials that are up to 12 inches thick. This makes them ideal for businesses that need to cut large pieces of metal or other materials on a regular basis.

Another benefit of waterjet cutting is that it produces very little waste. Unlike traditional cutting methods, there is no need to create a lot of scrap material when using a waterjet cutter. This can save your business money and help to reduce your environmental impact.

When it comes to commercial and industrial cutting, waterjet technology is one of the most versatile and precise methods available. Waterjet cutting can be used on a variety of materials, including metal, glass, stone, foam and even food.

There are many reasons why your business should invest in waterjet cutting. Here are just a few:

1. Precise and Versatile Cutting

Waterjet cutting is one of the most precise and versatile cutting methods available. Waterjet machines can cut virtually any material with incredible accuracy. This makes waterjet cutting ideal for a variety of applications, including the creation of prototypes, the fabrication of parts, and even the production of finished products.

2. Increased Productivity

Waterjet cutting can significantly increase productivity in your business. Waterjet machines are much faster than traditional methods of cutting, such as saws and lasers. This means that you can complete projects in a fraction of the time, allowing you to increase output and efficiency.

3. Cost-Effective

Waterjet cutting is a cost-effective way to cut materials. Waterjet machines use very little energy, so you can save money on your energy bills. In addition, waterjet cutting does not require the use of expensive cutting tools. This makes waterjet an affordable option for businesses of all sizes.

4. Environmentally Friendly

Waterjet cutting is an environmentally friendly way to cut materials. Waterjet machines use water instead of harmful chemicals or gases. This means that there is no risk of environmental contamination. In addition, waterjet cutting produces very little waste.

5. Safe

Waterjet cutting is a safe method of cutting materials. Waterjet machines are enclosed, so there is no risk of exposure to harmful chemicals or gases. In addition, waterjet cutting does not create dust or fumes, making it a safer option for your employees.

6. “Green” Cutting Method

Waterjet cutting is a “green” way to cut materials. Waterjet machines use water instead of harmful chemicals or gases. This means that there is no risk of environmental contamination. In addition, waterjet cutting produces very little waste.

7. Customizable

Waterjet cutting is a highly customizable method of cutting materials. Waterjet machines can be programmed to cut virtually any shape or design. This means that you can create custom parts and products for your business.

8. Increased Efficiency

Waterjet cutting can increase the efficiency of your business. Waterjet machines are much faster than traditional methods of cutting, such as saws and lasers. This means that you can complete projects in a fraction of the time, allowing you to increase output and efficiency.

9. Reduced Downtime

Waterjet cutting can help reduce downtime in your business. Waterjet machines are very reliable and require little maintenance. This means that you can keep your business running smoothly with minimal interruptions.

10. Investment in the Future

Waterjet cutting is an investment in the future of your business. Waterjet technology is constantly evolving, and new machines are being developed that can cut faster, more accurately, and more precisely than ever before. By investing in waterjet cutting, you are ensuring that your business will be able to take advantage of these advances and stay ahead of the competition.

Equipment Investment for Your Business

In manufacturing, the right piece of equipment is crucial to plant efficiency. And waterjet cutting could be that investment.

Waterjet cutting is a versatile, precise and cost-effective way to cut materials. Waterjet machines can cut virtually any material with incredible accuracy, making them ideal for a variety of applications. In addition, waterjet machines are much faster than traditional methods of cutting, such as saws and lasers. This means that you can complete projects in a fraction of the time, allowing you to increase output and efficiency.

Waterjet cutting is an investment in the future of your business, and by investing in waterjet cutting, you are ensuring that your business will be able to take advantage of the latest advances in waterjet technology.