The importance of saving money for a business cannot feel overstated. In tough economic times, companies that can afford to upgrade their operations and improve their products and services will be more successful than those that cannot. However, upgrading operations often costs money, and if a company does not have a cushion of cash reserves, it can be difficult or impossible to make these necessary improvements.

One way to create this cushion is to save money. By setting aside money each month, a business can accumulate a pool of funds that can be used for upgrading operations when needed. This pool of money can also help a business survive lean times, as you can draw upon it to cover operating expenses. It is especially true for the manufacturing side of things.

However, your manufacturing upgrade strategies can also be a way to save money, even when you have to invest in a few assets. Many advanced tools can save you money in the long run while allowing you to enjoy efficiency and productivity. Here are a few investments to consider to achieve that situation.

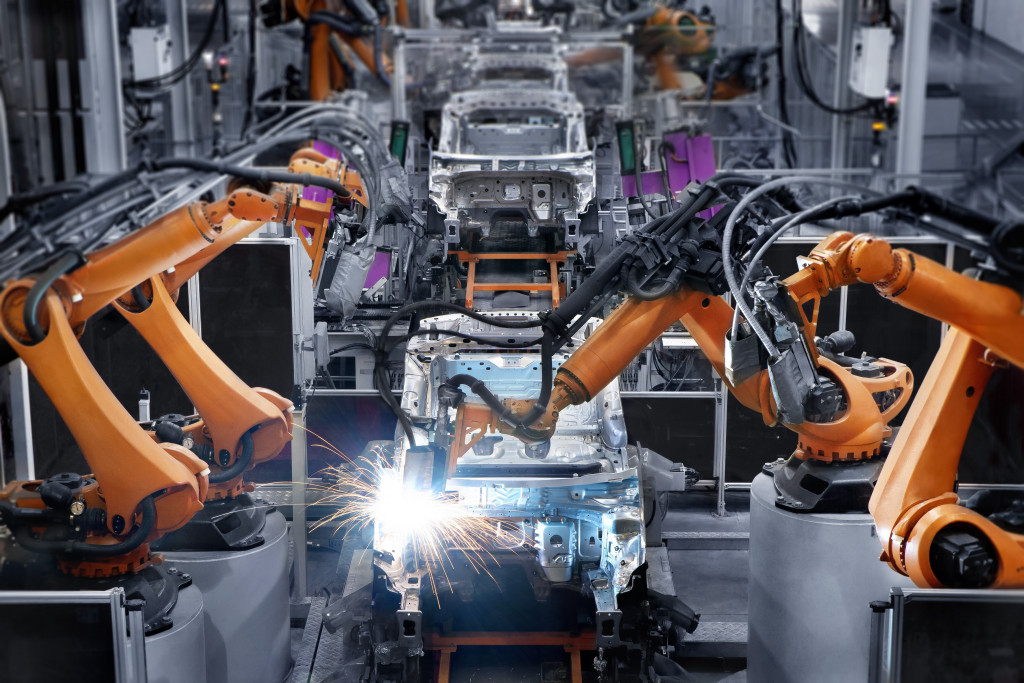

Automation Tools

One of the best investments you can make when upgrading your manufacturing process is in automation software and equipment. Automation can help you save money in several ways:

- Reducing the labor required to produce your products.

- Improving quality and consistency.

- Helping you use resources more efficiently.

Labor savings are perhaps the most obvious benefit of automation. With the right tools in place, you can significantly reduce the number of people required to produce your products. It can lead to reduced labor costs and increased efficiency and productivity. Automation also helps ensure consistent quality and accuracy in your products, which can help improve customer satisfaction. And lastly, automating your manufacturing process can allow better use of your resources, resulting in cost savings.

One of the most notable automation tools for manufacturing is computer-aided design (CAD) software. CAD software helps you streamline your design process, allowing you to create high-quality product designs more quickly and easily. In addition, CAD software can help you automate repetitive tasks, such as generating reports or drawings.

Another powerful automation tool is enterprise resource planning (ERP) software. ERP software helps you manage all aspects of your business, from inventory and order management to accounting and finance. ERP software can help improve efficiency and quality while reducing costs by automating critical business processes.

There are plenty of automation tools to utilize for manufacturing, making it a priority investment. It is just a matter of identifying the best for your operations.

3D Printing

3D printing is a great way to create accurate and oddly-shaped features when necessary for your products. With 3D printing, you can print objects with complex shapes that would be difficult or impossible to start using traditional manufacturing methods. It can be beneficial for prototypes and custom parts.

3D printing also allows you to print multiple versions of a part quickly and easily, making it a great way to test different design options. And because 3D printing uses less material than traditional manufacturing methods, it can also help reduce costs.

Overall, 3D printing is a great way to create accurate and complex parts quickly and easily. If you need a part that doesn’t fit into the traditional manufacturing mold, 3D printing is the perfect solution.

Another way to create oddly-shaped designs for your products is near net shape molding. It is a process that allows you to create parts very close to the final shape without needing machining or other finishing processes. It can lead to significant cost savings by reducing material waste and the time required to produce the parts. However, you might not have the equipment and resources to build those models. Fortunately, you can partner with a company that provides near net shape molding. They can offer the tailor-fit designs you need to improve your manufacturing efforts.

Machine Learning

Machine learning is artificial intelligence (AI) that allows computers to learn from data and experience. You can use machine learning for various tasks, such as recognizing patterns, making predictions, and providing recommendations. It is a revolutionary manufacturing creation, making it ideal for your operations.

Machine learning can be beneficial for manufacturing in several ways:

- It can help you automate the design process by creating models that automatically generate product designs based on your specifications.

- It can improve quality control by identifying product defects and improving the manufacturing process to prevent them.

- Machine learning can help you optimize your inventory management by predicting demand and ensuring that you have the right products in stock.

Overall, machine learning is a powerful tool that you can use to improve efficiency and quality while reducing costs.

Conclusion

Saving money is essential to any business but is especially critical for manufacturers. While these investments might mean more expenses in the long run, they can save you a lot of costs from your operations. If you’re not using them, you’re missing out on a significant opportunity to improve your processes.